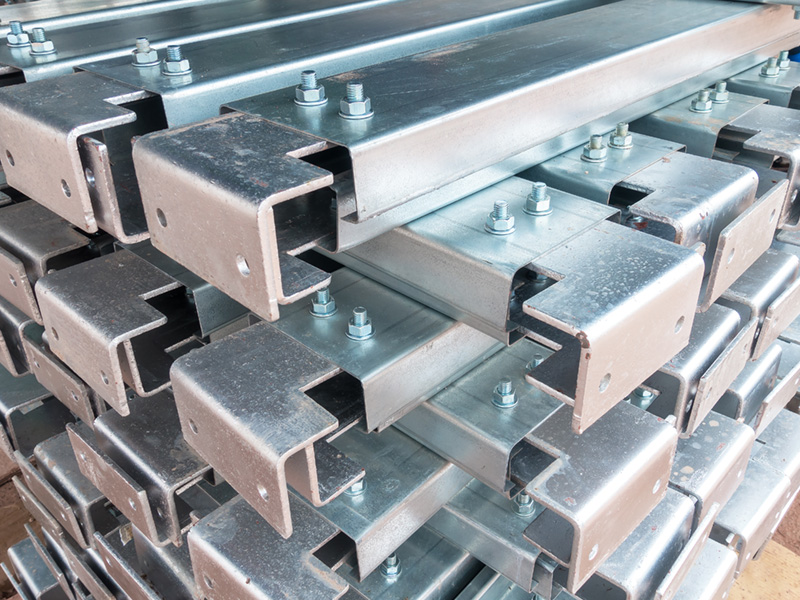

Electro-Galvanizing and Hot-Dip Galvanizing

The parts we produce are most often subjected to galvanizing.

Electro-Galvanizing

Electro-galvanizing is the most commonly used method for protecting metal surfaces.

During the electrolytic process, a zinc coating is applied to the base material, providing corrosion protection and giving the product an aesthetic appearance.

The standard zinc coating thickness ranges from 8 to 12 µm, but it can be adjusted to meet specific client requirements, up to 25 µm.

Hot-Dip Galvanizing

For long-term durability, hot-dip galvanizing is the most effective and cost-efficient method of protecting steel structures from atmospheric corrosion.

Hot-dip galvanized steel is used in many sectors, including:

- Construction

- Transportation

- Energy industry

- Agriculture

- Road infrastructure

During the process, several alloy layers are formed, ensuring excellent adhesion to the steel substrate.

The outer surface consists of a pure zinc coating.

The total layer thickness depends on the thickness of the steel structure and ranges from 45 to 280 µm, providing long-lasting resistance to environmental factors and ensuring an even, aesthetically pleasing coating.

Electro-Galvanizing and Hot-Dip Galvanizing