Grain Screw Conveyor with Enlarged Loading Hopper

An excellent solution for the quick unloading of trailers equipped with discharge openings. The grain is directly poured into a wide hopper, from where it enters the working chamber of the screw conveyor through the inlet opening. This transportation method minimizes the need for operator intervention.

Screw conveyors are used in agriculture, warehouses, by feed manufacturers, and animal breeders.

The motor and drive system are located at the base of the conveyor, stabilizing the machine by adding weight while not stressing the tubular segments. This design allows easier access to the drive system for maintenance and adjustment.

The discharge height is adjustable using a crank and a wire rope winch mounted under the tube at an optimal height for the user. The gear ratio is selected to ensure relatively easy and safe raising and lowering of the discharge.

The massive frame-based chassis, made of solid steel profiles, provides high stability during both operation and transport.

These types of screw conveyors belong to the category of high-performance transport units. They feature an enlarged loading hopper, a sturdy chassis, and the added advantage of being attachable to a tractor via a detachable drawbar, allowing easy transport around the farm.

Gallery

Key Features:

- High real transport efficiency – up to 15, 30, and 50 t/h;

- Adjustable discharge height using a crank, based on a winch system integrated into the chassis;

- Modular (segmented) conveyor design;

- Adjustable height and inclination angle of the loading hopper (2x1 m dimensions);

- The screw is supported by bearings in each segment (every 2 meters), significantly improving durability, extending the lifespan of support bearings, stiffening the external tube, and ensuring quiet operation;

- Large wheels suitable for any type of terrain;

- The conveyor can be attached to a tractor and transported – equipped with a detachable drawbar;

- Transport efficiency adjustable via a shutter;

- The conveyor can operate and be stored outdoors – hot-dip galvanized with a thick protective coating and an aesthetically glossy surface;

- Suitable for loading grain silos through an opening in the top cover;

- Low purchase and operating costs, high mobility, and versatility compared to other transport devices.

Technical Specifications:

| CONVEYOR SYMBOL | TUBE DIAMETER (mm) | CAPACITY(t/h) | MOTOR POWER (kW) | MIN. LENGTH (m) | MAX. LENGTH(m) |

|---|---|---|---|---|---|

| 200/10-12/OC-DR | 200 | 30 | 7,5 | 10 | 12 |

| 200/12-14/OC-DR | 200 | 30 | 9 | 12 | 14 |

| 250/10-12/OC-DR | 250 | 50 | 11 | 10 | 12 |

| 250/12-14/OC-DR | 250 | 50 | 11 | 12 | 14 |

When ordering, please refer to the conveyor symbol. For example, 250/10-12/OC–DR, where:

- 250 indicates the conveyor tube diameter in mm,

- 10 is the minimum conveyor length in meters,

- 12 is the maximum working length (achieved by purchasing an additional extension segment),

- OC means hot-dip galvanized conveyor,

- DR means a bottom drive system, material intake via a loading hopper, and a frame-structured chassis.

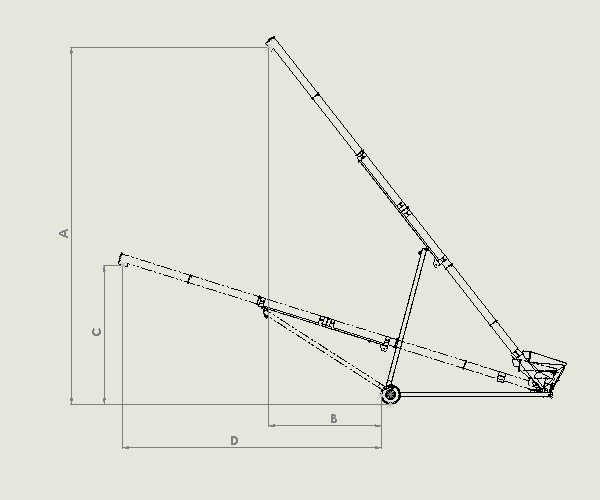

Tube Length Dimensions

| Tube Length Dimensions (m) | A | B | C | D |

|---|---|---|---|---|

| 10 | 7,5 | 1,6 | 3,1 | 5,2 |

| 12 | 9 | 3,1 | 3,7 | 7,1 |

| 14 | 10,5 | 4,6 | 4,3 | 9 |

Extension Segments:

| SEGMENT SYMBOL | NOMINAL LENGTH (m) | TUBE DIAMETER (mm) | COATING |

|---|---|---|---|

| 200/1/OC | 1 | 200 | Galvanized |

| 200/2/OC | 2 | 200 | Galvanized |

| 250/1/OC | 1 | 250 | Galvanized |

| 250/2/OC | 2 | 250 | Galvanized |

When ordering, please refer to the segment symbol, e.g., 250/2/OC, where:

- 250 indicates the conveyor tube diameter in mm,

- 2 is the segment length in meters,

- OC means hot-dip galvanized conveyor.

Optional rotating discharge chutes are available for these conveyors.

Additional Equipment

Extension Segment

Rotating Discharge Chute

Hopper Cover

Swivel Wheel Set

Award-Winning Product at Trade Fairs!